The great spell of success in the fast-paced, ultra-competitive world of today is to be the first to get your product to market without sacrificing product quality in terms of performance or reliability. Getting it right the first time has become a necessity to gather initial profit gains as well as to lower the cost and time associated with manufacturing the product.

The ability to be the best and first to market your product is limited to how well you can structure your PCB Assembly and prototype process to ensure the manufacturability of the PCB at its own design stage by identifying the initial problem design in the design stage itself thus eliminating the need for prototyping PCBs back spinning.

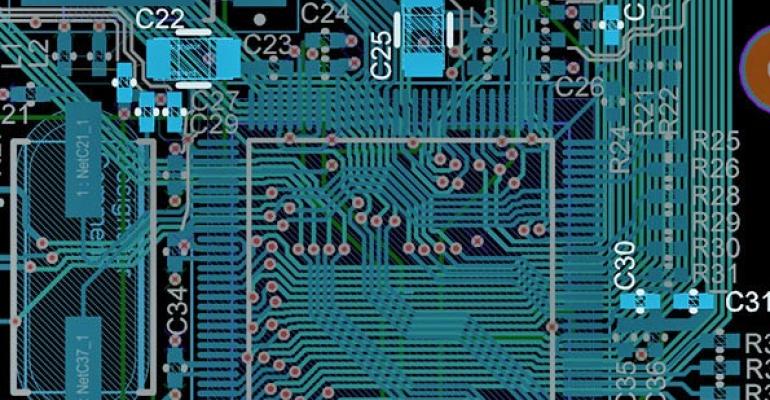

The optimized design can reduce the cost and performance issues during PCB prototyping

It is not uncommon for PCB Assembly Services to add more complexity to PCB design that is required for performance purposes which can sometimes cause problems for manufacturers, especially if design components require special processes or machines that may not be available with the manufacturer. In general, fewer components on the PCB, the greater the chances of success and also less likely to invoke backspin due to design issues. Also, a lower number of components on smaller PCBs is the time and cost involved. That is why specialist PCBs emphasize the importance of optimizing the design for the required performance rather than trying to adapt too many components and features that can increase costs without adding value according to the product.

Knowing your partner’s manufacturing and capabilities and processes can help you avoid running into problems later

The best way to reduce the number of PCB Prototype spins is to bind with the PCB fabricator in the early stages of the PCB design itself. A good PCB Fabricator can provide you valuable input design that not only helps improve the quality and performance of your product but can help you reduce the time and cost involved in PCB iteration and re-spin. Each PCB Manufacturer or fabricator has his own ability and strength, for example, they can only produce certain dimensional PCBs or can only produce PCB of a certain degree of complexity. Unless you have taken the time to understand the strengths and limitations of PCBs partnering with manufacturers during the design stage itself can help you avoid PCB prototyping back spinning by ensuring your PCB design matches the design specifications required by the manufacturer.

Ensure successful Design for Manufacturing (DFM) tests before PCB release fabrication and manufacturing

There are ways to ensure manufacturability. Partner with your PCB manufacturer to run the design through the DFM tool to ensure the design is error-free and ready manufacturing. Verifiability for manufacturing is an important step that can help you save a lot of time and money on PCB Prototyping re-spin, so make sure you make an integral part of your process step.

Don’t miss the scheme

Building the layout from complete schematic will gives you some reference and helps ensure that all the connection of layouts will be complete. The schematic is your visual representation of your circuit. This lets you organize components close to their functional counterparts and the location they will be placed. When every pin on each component is represented by a schematic symbol, disconnect it easy to recognize. This scheme helps you determine if the basic circuit design rules have been followed by visualizing the design.

Optimize for budgeted and out of budget costs associated with prototypes with the derived cost to value ratio

Some of the costs appear big and causes they may seem a waste of money but can add significant savings later. For example, many organizations prefer to work with small design teams to save on labor costs. But in some cases, adding 1-2 others to the team might lead to faster design turnover and reduce PCB Prototype spin-off because higher quality checks result in time and cost savings.